Block 3, MHDI Building, 86 Le Trong Tan, Phuong Liet Ward, 100000 Hanoi City, Vietnam

Blog

Welcome to our Shop

Chrome-plated steel bearings cannot withstand temperatures up to 120°C in continuous use. They also cannot be used continuously at temperatures up to 150°C. At temperatures above a certain level, the strength of chrome-plated steel bearings decreases, and their dimensions vary more than stainless steel.

GMW offers miniature ball bearings for Metric and Inch series as below:

- Flanged miniature ball bearings in Chrome steel

- Stainless Steel Miniature Bearings for high precision

- Stainless Steel Miniature Flange Bearings

GMW offers material:

- SAE52100 / SUJ2 / GCr15 steel or equivalent

- 440C (alternatively 304 or 420D) stainless steel

GMW offers lubricant solution:

- High temperature grease up to 150°C with base-oil Lithium

- High temperature grease up to 200°C with base-oil Polyete perflorua

Tolerances class: Grade P0, P6, P5, P4

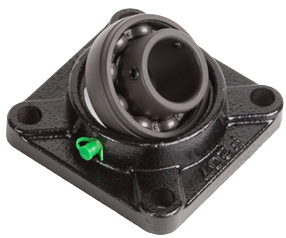

Flanged Miniature Bearings in Chrome Steel

Chrome steel bearings can handle temperatures up to 150°C when used continuously, with a steel retainer and proper lubrication. At temperatures above 150°C, the strength of chrome steel bearings decreases.

For detailed specifications in inch and metric series on load capacity and speed ratings, please refer to the technical drawings available by clicking ”More”. While our chrome steel bearings are designed for high load and speed applications, it’s recommended to operate them below their maximum rated values to ensure optimal bearing life.

Stainless Steel Miniature Bearings for high precision

Stainless steel bearings, with a stainless steel retainer and a suitable high-temperature lubricant, enable operation at temperatures ranging from a steady 150°C to intermittent peaks of 200°C.

For comprehensive technical insights into the inch and metric series, click on ‘More’ provided below for detailed technical drawings showcasing load and speed data for the bearings. The load ratings shown are for S440C stainless steel bearings.

Stainless Steel Miniature Flange Bearings

These bearings, with a stainless-steel retainer and a suitable high-temperature lubricant, can be operated at temperatures of 150°C constant or up to 200°C intermittent. At temperatures exceeding these thresholds, the load capacity of the stainless steel may decrease.

Click on “More” below to display technical drawings of the bearings, comprehensive technical insights, and inch and metric series with load and speed data. The load ratings shown are for S440C flanged bearings.

Latest news

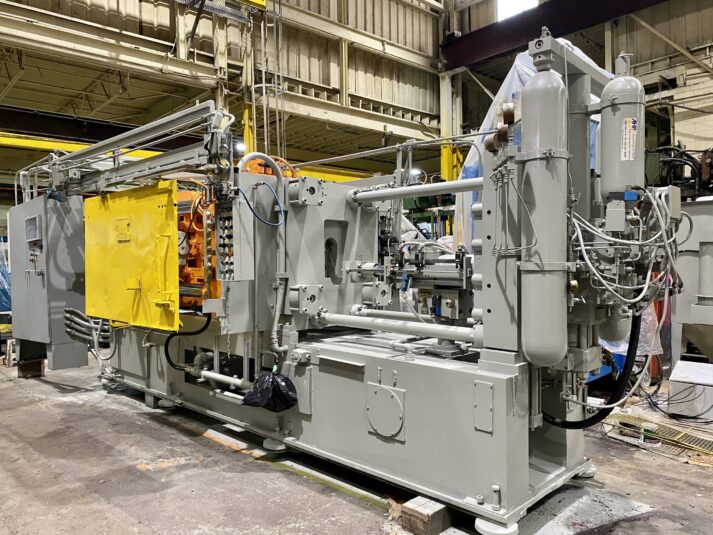

Application of high-temperature bearings mounted on the bucket arm of a die-casting machine

In the high-pressure die casting process, molten aluminium or aluminium alloy is ladled from the furnace and poured into the mould at high speed and pressure.

Depending on the metal used, the ladle feeds the material into the mould continuously with the molten metal at a temperature of 600°C – 700°C.

GMW – 350°C heat-resistant bearings are made of heat-resistant material and lubricated with a special grease. This lubricant allows stable operation even at temperatures up to 350°C.

GMW – Heat-resistant bearings are manufactured with a ring atomic mass, high performance, and friction. Manganese phosphate coatings help the bearings ensure corrosion resistance; good adhesion of lubricants will ensure safe and efficient operation of equipment in production.

Benefits of GMW Heat-Resistant Bearings for Aluminium Bucket Arm

- The MoS₂ hard glue compound in the bearing increases the load capacity and improves the alkali resistance of the bucket arm robot.

- The bearing is designed to withstand very high temperatures up to 350 degrees Celsius at the bridge mounting location.

- Easy to disassemble and maintain after a long period of use.

- Grease can withstand humid environments, corrosive environments and salt.

- Highly economical because the bearing itself generates lubricating compounds to help the bucket operate smoothly

- Reduces friction well, prevents the bucket from locking under the temperature of the furnace

- The product contains different types of solid glue to help achieve high load-bearing and heat-resistant efficiency.

All heat-resistant bearings, bearing symbols HT1, HT2, HT3 and HT4, have technical product codes, no grease-slip products, one heat-resistant steel product (Z) or both sides (2Z).

Bearings with bearing temperature resistant to 350°C have standard product codes such as:

6000…6001…6002…6003…6004…6005…6006 up to 6010…6020

6200…6201…6200…6203…6204…6205…6206 up to 6210…6220

6300…6301…6302…6303…6304…6305…6306 up to 6310…6320

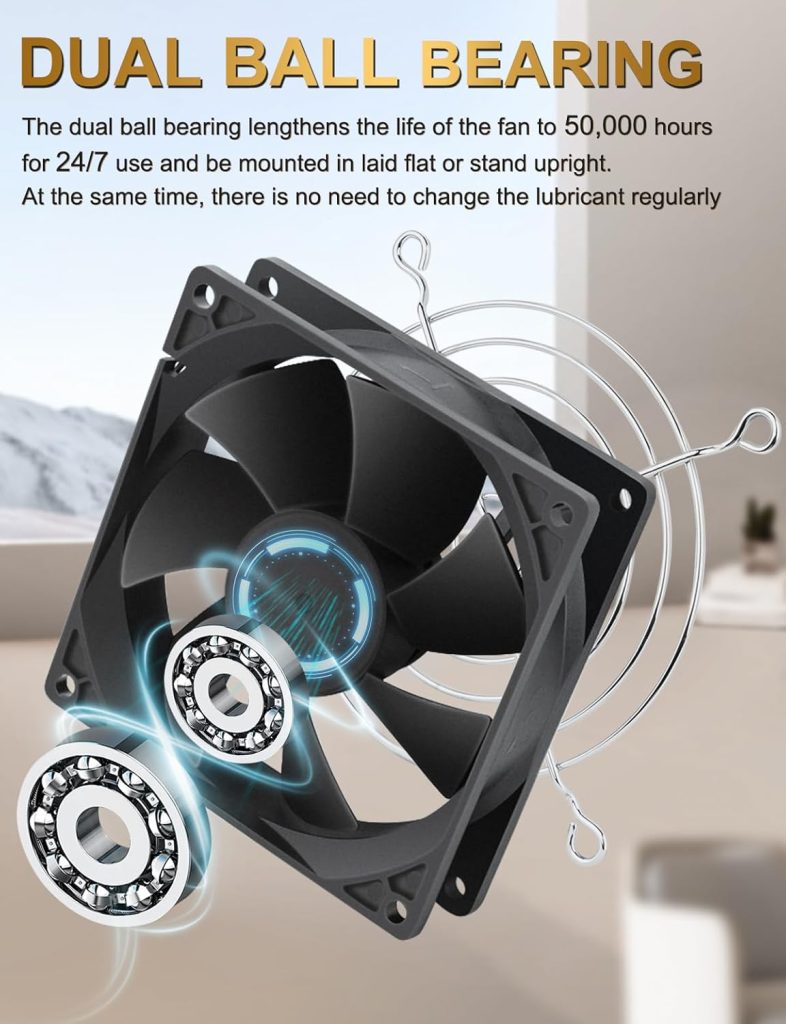

Heat-resistant bearings in the fan system that sucks or pushes hot air from the drying oven

Industrial ventilation fans using heat-resistant bearings are professional cooling systems for factories. The function of ventilation fans is to help circulate, dissipate heat, dissipate odours and dehumidify quite well. Bringing a clean, dry and safe space for machinery. As well as making workers work better. So most factories use them.

During operation in harsh environments with the purpose of pushing hot air, the temperature generated in the bearing is from 200°C to 300°C. At the shaft end, the bearing can have a temperature of 180°C ~ 250°C.

With bearings including a C3 technical slot. Process temperature and environmental testing with high temperature. Will clean the lubricating chemicals leading to bearing clogging. Not ensuring high-speed operation will destroy the ring at the support knee. Usually to solve this, soak the whole in grease. And enhance lubrication.

Cooling solutions are diverse, such as massage cooling with circulating water and cooling by mounting on the fan shaft with the desire for long-term operation. The disadvantages of these solutions are that they are very time-consuming and costly for maintenance, oil pulse addition, grease addition, and replacement costs. Wear from the operation of the problem.

Bearing products withstand temperatures up to 300 degrees C.

To solve the disadvantages in the management and operation of equipment. Our engineers have researched and produced a product line that can withstand temperatures up to 300°C. The characteristics of that bearing product line are:

- Withstand friction at high speed.

- The product is designed for easy installation and operation.

- Withstand harsh working environments: from 250°C to 300°C.

- Hardness and durability ensure environments with different temperature ranges with PTFE-based lubricating grease solutions.

- The product is applied according to drawings or customer requirements suitable for the equipment.

GMW brand heat-resistant bearing products have been practically applied to hot air exhaust fans in electrostatic painting furnaces and have produced excellent results. With hot air exhaust fans operating an average of 16 hours/day, maintenance will be required within 16 months of the equipment being put into operation.

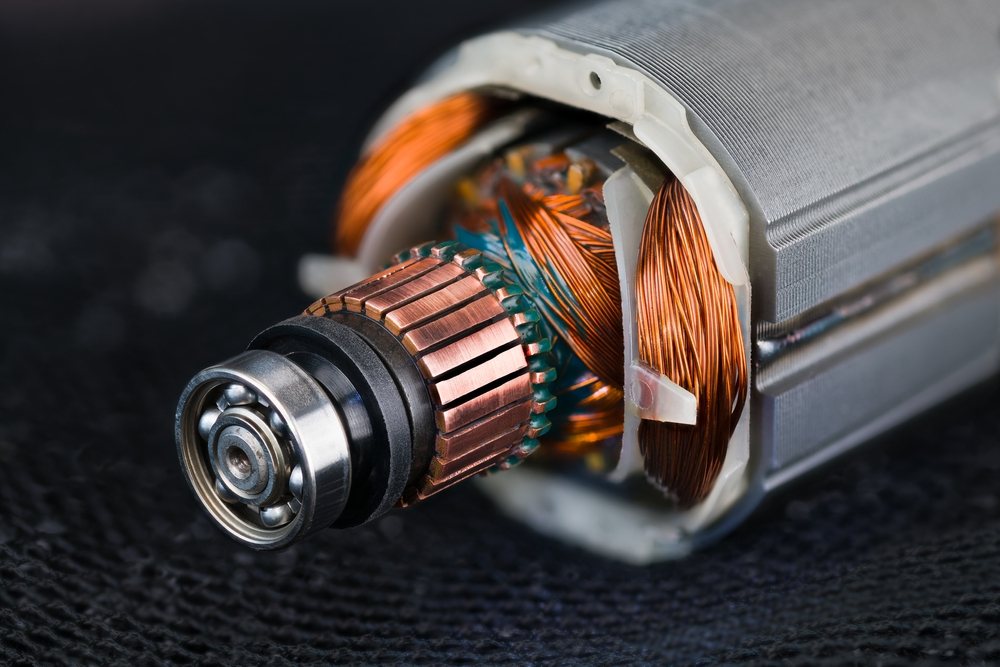

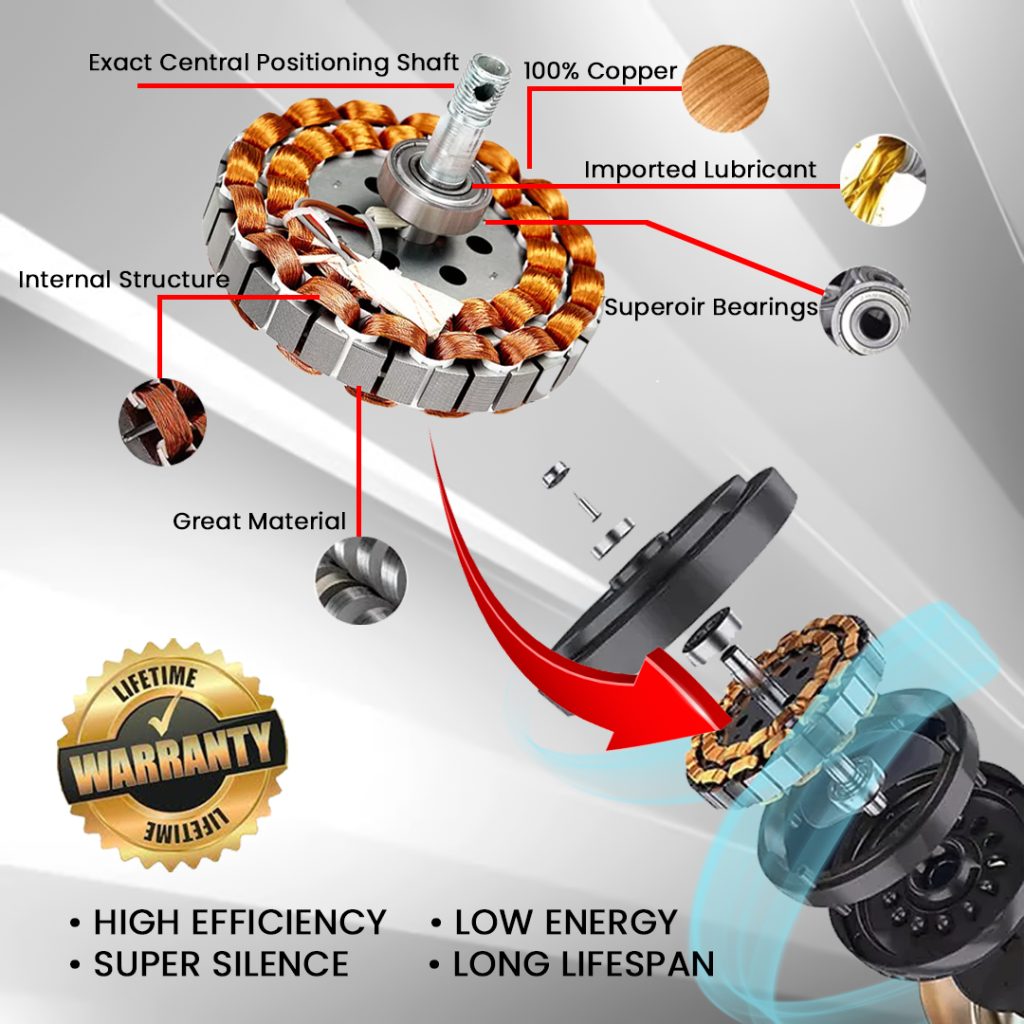

Select heat-resistant bearings for high-temperature electric motors.

According to statistics, up to 60% of equipment and machinery is damaged due to improper lubrication in high-temperature environments. Especially electric motors. Therefore, the role of electric motor heat-resistant bearings is extremely important. However, not everyone knows how to choose heat-resistant grease to maximise its effectiveness and meet the needs. We will find out together in the article below.

The effect of heat-resistant bearings for electric motors

Heat-resistant bearings in general and heat-resistant grease for electric motors in particular have many great uses. They are indispensable in every industry as well as any engine or device. The uses of heat-resistant bearings for motors are:

-

Reduces friction and wear on bearings in gearboxes, rollers, and electric motor shafts.

-

High-strength, wear-resistant steel material

-

Grease will create an oil film to separate the metal parts from direct contact with the bearings in an electric motor.

-

Cooling and sealing the rotating shaft parts. Thereby preventing dust and other agents from damaging and breaking the machine. The engine will operate more smoothly, durably and flexibly.

How to choose the most standard heat-resistant bearing for an electric motor

Operating speed

The rotation speed of the heat-resistant bearing must be suitable for the transport and operating speed of the electric motor. You should choose a bearing for the electric motor with a rotation speed suitable for the equipment to be installed for the highest efficiency.

Consistency

This consistency is specified by the National Lubricating Grease Institute (NLGI). It ranges from 000 to 6. In electric motors with horizontal shaft configuration, NLGI level 2 consistency is used, which is available in the bearing. For vertical shaft configuration, the consistency used is NLGI 3.

Antioxidant capacity

The level of oxidation resistance is very important for high-temperature grease in bearings. The high-temperature grease you choose to use must have excellent oxidation resistance. These greases are tested by the American Society for Testing Materials (ASTM) and have proven to have good oxidation resistance even when operating continuously in harsh environments. Greases with high oxidation life D3336 or high temperature life test (DIN 51821 FE 9) are the products you should choose to use.

Abrasion resistance

When choosing heat-resistant bearings for electric motors, you should choose bearings made of high-strength steel and grease without extreme pressure additives.

Selection of dropping points of greases available in heat-resistant bearings

Our popular electric motor heat resistant bearing products are:

250°C heat resistant bearing (T250)

GMW deep groove ball bearings with suffix T250 are suitable for high rotation speeds and temperatures up to 250°C. All T250 deep groove ball bearings have the following advantages:

- Made from AISI 52100 steel material

- C3 or C4 clearance design compensates for temperature induced distortion

- Can withstand temperatures up to 250°C

- Special polytetrafluoroethylene (PTFE) heat-resistant grease for smooth movement

- Riveted steel plate roller cage provides high stability but low friction

Full range of product codes such as:

- 6000 … 6022

- 6200 … 6222

- 6300 … 6322

- There are many types to choose from: No grease cap (Open), two heat-resistant steel caps (2Z) or Acrylonitryle Butadiene (NBR) rubber cap (2RS1)

The GMW deep groove ball bearing suffix T250X is an extension of the T250 series; it is machined with an additional manganese phosphate coating and is suitable for medium speeds with temperatures up to 250°C. All T250X deep groove ball bearings have the following advantages:

-

Made from AISI 52100 steel material

-

C4 clearance design compensates for temperature-induced distortion

-

Stable operation at temperatures up to 250°C (even up to 280°C the bearing still operates stably)

-

Manganese phosphate (Mn₃(PO₄) 2) Surface coating (according to EN ISO 9717) ensures enhanced protection against corrosion.

-

Special polytetrafluoroethylene (PTFE) heat-resistant grease for smooth movement

-

Riveted steel plate roller cage provides high stability but low friction

Full range of product codes, such as:

-

6000 … 6022

-

6200 … 6222

-

6300 … 6322

-

There are many types to choose from: No grease cap (open), two heat-resistant steel caps (2Z) or an acrylonitrile butadiene (NBR) rubber cap (2RSH)

200°C heat-resistant bearing (T200)

GMW deep groove ball bearings with the suffix T200 are suitable for high rotation speeds and temperatures up to 200°C. All T200 deep groove ball bearings have the following advantages:

-

Made from AISI 52100 steel material

-

CN or C3 clearance design compensates for temperature-induced distortion

-

Adaptable to temperatures up to 220°C (effective operating temperature 200°C)

-

Special heat-resistant grease (POLYUREA) for smooth movement

-

Riveted steel plate roller cage provides high stability but low friction

Full range of product codes, such as:

-

6000 … 6022

-

6200 … 6222

-

6300 … 6322

-

There are many types to choose from: No grease cap (open), two heat-resistant steel caps (2Z) or an acrylonitrile butadiene (NBR) rubber cap (2RSH)

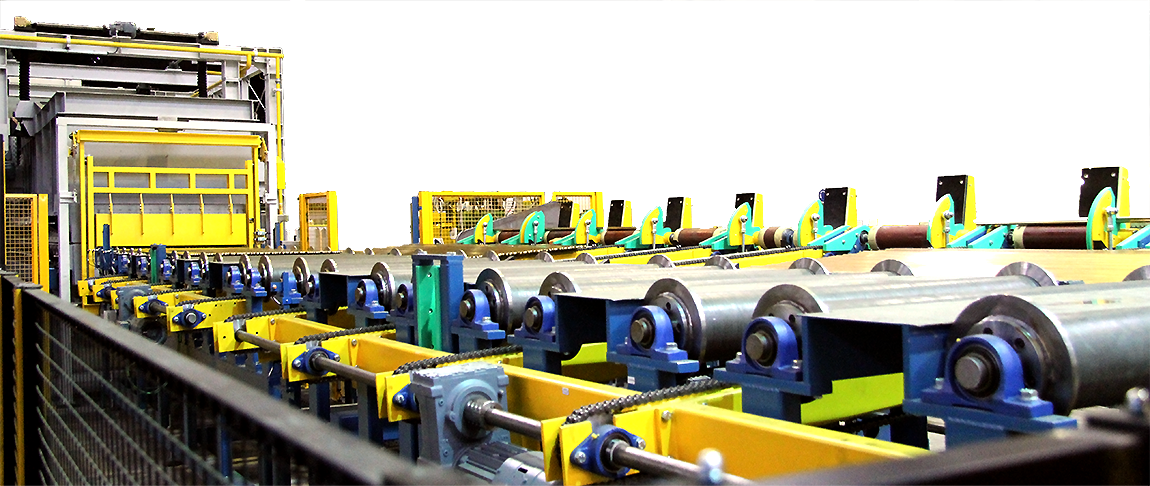

High-temperature bearings used in drying oven systems and heat presses

Many bearings operate in high-temperature environments – but few lubricants can withstand them. High-temperature bearings incorporate dry lubrication for very high-temperature applications, providing customers with benefits.

In such applications, where bearings are subjected to very high temperatures (in the range of 200°C – 350°C), conventional lubricants such as greases and oils deteriorate rapidly, resulting in poor lubrication. Dry lubricants do not deteriorate at high temperatures, can handle heavy loads and have high thermal stability. This is why dry lubricated bearings have significant potential, especially in the metalworking industry.

We have many years of experience in manufacturing dry lubricated bearings. These bearings are commonly used in drying oven rollers, heat presses and continuous baking ovens. With the introduction of DryLube bearings, a wide range of dry lubricated bearings can be applied to virtually any equipment operating in high-temperature environments – including roller bearings and plain bearings.

The DryLube solution combines graphite and molybdenum disulphide (a dry lubricant). The high durability of the dry lubricant is due to its ability to carry heavy loads without creating metal-to-metal contact. The dry lubricant also has good adhesion to the substrate surface even under high shear stresses.

For graphite, the lubricating properties are further enhanced by the presence of graphite layers, which reduce shear and frictional forces. Graphite functions as a lubricant at temperatures above 400°C. To further improve the performance or extend the life of DryLube bearings, dry lubricants are combined with additives and lubricating nanoparticles.

To create DryLube bearings, dry lubricants and a resin binder are injected into the void space in the bearing surrounding the rolling elements and raceways. A curing process is followed to ensure the lubricants solidify. This makes the bearing extremely versatile and capable of meeting virtually any high-temperature requirement.

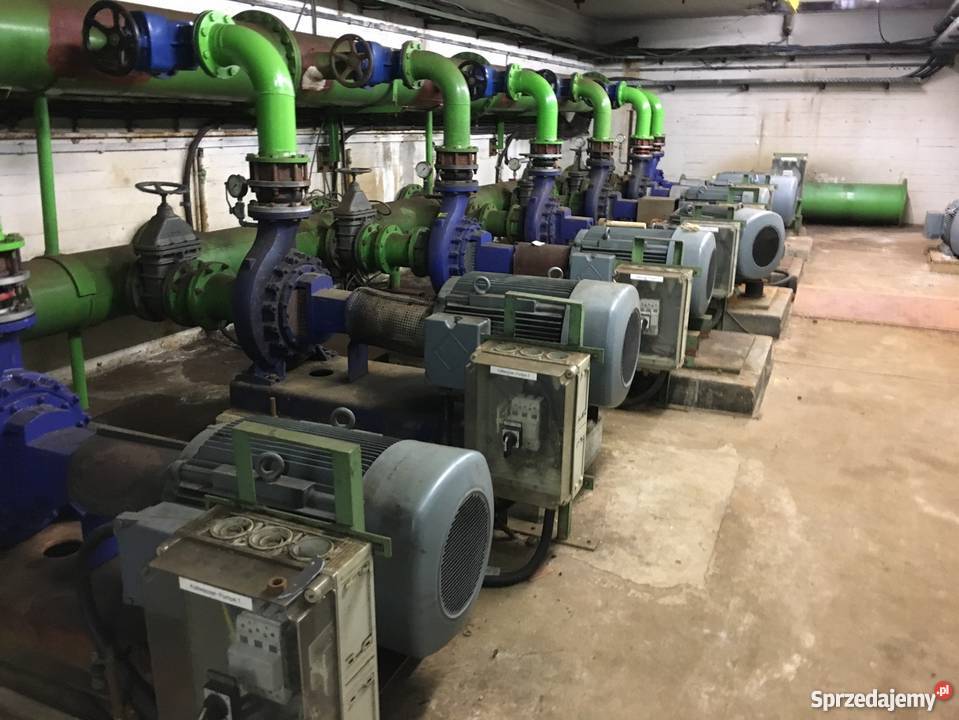

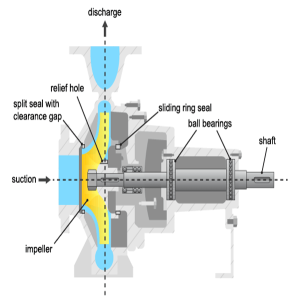

Heat resistant bearings used to install heat transfer oil pump motors

Hot oil pump or heat transfer oil pump is a type of industrial pump specially designed to pump liquids, solutions, oils at high temperatures, without fried particles with a heat resistance level of up to 350 degrees Celsius and effective corrosion resistance. Hot oil pump plays an important role in the process of exploiting, processing and transporting oil..

The structure of the hot oil pump consists of main parts such as: Pump housing, Rotor, Heat-resistant bearings , sealing accessories. The pump head is connected to the motor through 3 heat-resistant belts. In terms of structure, the hot oil pump has a simple structure, easy to control, easy to replace, install and use.

Understanding the importance of heat-resistant bearings installed for heat transfer oil pump motors. Our company has developed a line of bearings with the suffix T250 and T250X with the following characteristics:

- Made from AISI 52100 steel material

- C3 or C4 clearance design compensates for temperature induced distortion

- Adaptable to temperatures up to 250°C to a maximum of 300°C

- Special polytetrafluoroethylene (PTFE) heat-resistant grease for smooth movement

- Manganese phosphate (Mn3(PO4)2) surface coating (according to EN ISO 9717) ensures enhanced corrosion protection (T250X series only)

- Riveted steel plate roller cage provides high stability but low friction

Full range of popular product codes such as:

- 6000 … 6022

- 6200 … 6222

- 6300 … 6322

- There are many types to choose from: No grease cap (Open), two heat-resistant steel caps (2Z) or Acrylonitryle Butadiene (NBR) rubber cap (2RS1)

Download our PDF catalog for GMW High-temp Deep Groove Ball Bearings for fast speeds here: