Block 3, MHDI Building, 86 Le Trong Tan, Phuong Liet Ward, 100000 Hanoi City, Vietnam

1. Characteristics of Heat-resistant Lubricating Grease – HT4 Paste contains lubricants, including:

- Molybdenum disulphide (excellent in heavy-duty lubrication).

- PTFE (excellent in lubricating plastics).

- Lead and soft metals (excellent in lubrication at extreme temperatures).

- Prevents thread burn and wear over long periods of time if applied in a thin layer when assembling, tightening bolts, etc.

HT4 Paste can withstand temperatures from 0°C to 450°C in humid and chemical environments.

- Has a long service life in high-temperature, heavy-load lubrication applications, both low-speed and high-speed.

- Sealing: HT4 Paste does not flow like soap-based greases, and therefore its consistency and composition remain unchanged at high temperatures. Provides good sealing and continuous lubrication even in areas subject to vibration.

- HT4 Paste is also effective in corrosive environments.

2. Product application:

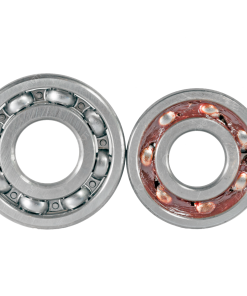

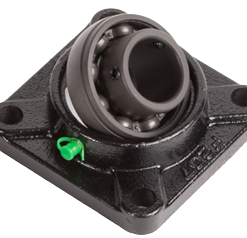

- Used to lubricate parts such as bolts, nuts, heat-resistant bearings, and machinery in high-humidity and high-temperature environments exposed to chemicals.

- Suitable for preventing thread burnout at the screw head and nozzle head of the press machine.

3. Method of use:

- Clean the part to be serviced with cleaning solution.

- Use your hands to apply enough grease to seal the surface and joints that need protection.

Note:

- Bearing Housing: The bearing housing should be designed to completely flush out old lubricant when re-greasing. Additionally, the bearing should be disassembled for routine maintenance, and the entire grease volume replaced.

- Health and Safety: HT4 Paste is unlikely to present any significant health or safety hazard when used as recommended, and good industrial hygiene and safety standards are maintained.