Block 3, MHDI Building, 86 Le Trong Tan, Phuong Liet Ward, 100000 Hanoi City, Vietnam

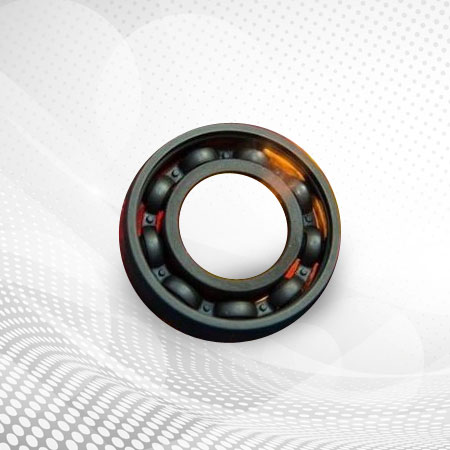

GMW HT4U (Ultra) high-temperature deep groove ball bearings are an upgraded version of the HT4 series. The newly designed HT4U (Ultra) bearings play an important role in the efficient operation of many different types of equipment and are an indispensable part of industrial applications, especially those operating in extremely high-temperature environments. HT4U (Ultra) bearings are ideal for applications where continuous maintenance is difficult or impossible.

The product is coated with manganese phosphate and is suitable for low speeds at temperatures up to 450°C. All HT4U deep groove ball bearings have the following characteristics:

- Made from AISI 52100 / SUJ2 / GCr15 steel material

- C5 clearance design compensates for temperature-induced distortion

- Stable operation at temperatures up to 450°C

- Manganese phosphate (Mn₃(PO₄) 2) Surface coating (according to EN ISO 9717) ensures enhanced protection against corrosion.

- Special molybdenum sulphide (MoS₂) grease in mineral oil forms a highly effective lubricating layer on rubbing and sliding surfaces. This reduces friction, allowing parts to operate more smoothly and providing greater economic benefits for bearings.

- Riveted steel plate roller cage provides high stability but low friction

Full range of product codes, such as:

- 6000 … 6022

- 6200 … 6222

- 6300 … 6322

- There are many types to choose from: No seal (open), two heat-resistant steel seals (2Z)

Its advantages are as follows:

1. Reduced maintenance requirements: HT4U suffix bearings operate continuously under harsh conditions up to 500 degrees Celsius. This reduces the need for frequent maintenance, thereby increasing the operating efficiency of the machine.

2. Higher load capacity: Using lubricating material, the bearing has higher load capacity. This means better performance and longer machine life.

3. High Temperature Resistance: Due to their higher temperature characteristics, HT4U can operate at higher temperatures than conventional ball bearing systems. This makes them suitable for use in applications where high temperatures are frequently encountered.

4. Reduced Friction: HT4U have lower friction coefficients than other systems, meaning they provide minimal moving force. This reduces wear and tear on equipment and extends equipment life.